Innovative Solutions to Preventive

Maintenance and Detection

With our systems you can detect problems before break downs occur.

Examples

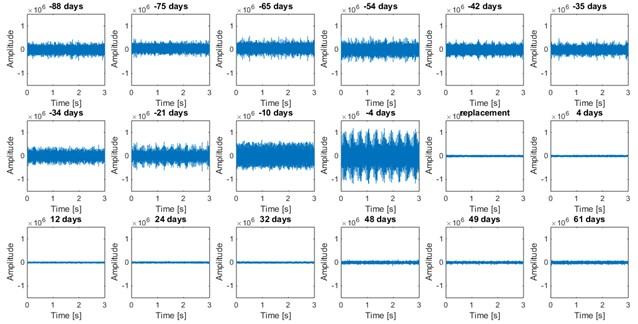

Vibration Sensors

Well placed vibration sensors can monitor smooth running parts and identify when parts are starting to have issues, due to lack of lubrification, wear of bearing, over heating etc..

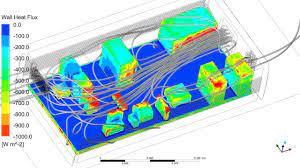

Heat Sensors

Avoid catastrophic problems before they occur.

Strategically placed sensors can prevent production downtime and equipment damage.

Lubrification Sensors

Automate lubrification and know when lubrification is not taking place as expected.

Features and Benefits

Wireless - No need to pull cables

Long Range - No need to install many communication terminals.

Programmable - Can know when something is not going as planned

Focus on Problems : Identify where problems are starting and focus your resources there.